Metal Spinning

What is Metal Spinning!

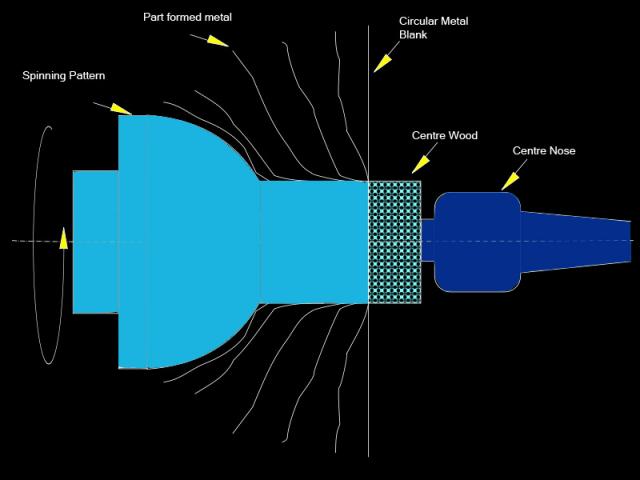

- A circular metal blank is concentrically clamped against the spinning pattern using the centre nose and centre wood as shown.

- While the motor turns the spindle, rotating the pattern at high speeds, a forming tool or rollers are driven against the material to partially move it further with each pass or stroke.

- Many passes are normally needed to form the material onto the pattern, and the type and thickness of material will also make a difference in how it forms, this is very important to prevent premature failure through splitting or buckling.

- A variation of this process is called Shear Forming, generally used to form cone shapes where one pass is required.

- Most circular items can be made by metal spinning as the process is very flexible and the range of products that we are able to manufacture is vast.

How Metal Spinning Works!

Why Choose Metal Spinning!

- Lower Tooling Costs

- More Flexibility with Design of Product

- Short Lead Times

- Improved Tensile Strength

For all Metal Spinning enquiries please feel free to give us a call on Tel: 0151 424 5225 or Email: sales@metalspinning.co.uk